R & D

오랫동안 축적된 핵심역량을 바탕으로 고객이 원하는 신제품, 신기술 개발에 주력하고 있습니다.

자동차 촉매개발

가솔린 자동차용 촉매

가솔린 자동차 촉매는 휘발유, LPG 연료를 사용하는 차량에서 배출되는 CO, HC, NOx를 동시에 제거하는 촉매로서 Euro-3 에서부터 Euro-6 배출가스 규제를 만족할 수 있습니다. 또한 배기량에 따라 경형, 소형, 중형, 대형 차량에 적합한 촉매를 보유하고 있습니다.

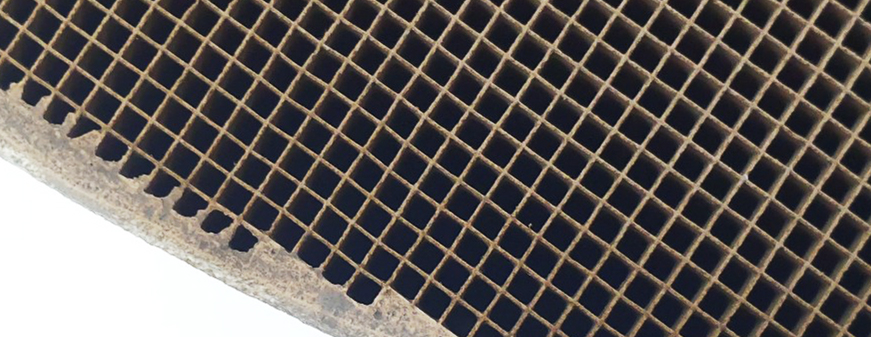

디젤 자동차 촉매

디젤 자동차 촉매는 경유를 사용하는 차량에서 배출되는 CO, HC, NOx, PM을 제거하는 촉매로서 Euro-3 에서부터 EURO-6 규제에 대응 가능한 촉매를 개발 완료하였습니다. DOC (Diesel Oxidation Catalyst), DPF (Diesel Particulate Filter), SCR (Selective Catalytic Reduction) 촉매, AOC (Ammonia Oxidation Catalyst), 질소산화물과 입자상 물질을 동시에 제거하여 촉매 및 장치의 크기를 줄일 수 있는 SDPF(SCR on Filter) 촉매 및 시스템 기술을 개발 완료하였습니다.

개인정보 취급방침

본사 : 충남 아산시 온천대로 1122번길 46-5 (득산동 312-26) Tel : 041-531-0657 / Fax : 041-531-0659

서울사무소 : 서울시 송파구 송파대로 260(가락동)제일오피스텔 906~907 Tel : 02-744-1777, Fax : 02-443-0054