R & D

오랫동안 축적된 핵심역량을 바탕으로 고객이 원하는 신제품, 신기술 개발에 주력하고 있습니다.

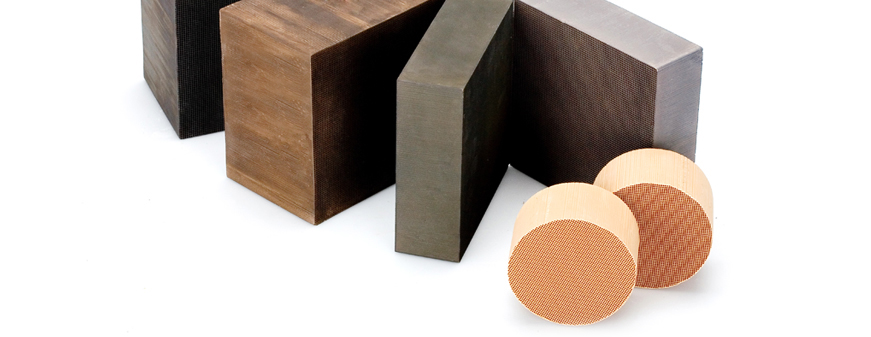

환경 촉매 개발

내연 기관용 촉매

중대형 디젤엔진 배가스의 후처리시스템에 적합한 DOC, DPF를 개발하였습니다. 운전 조건 및 연료에 따라 촉매를 특화하였으며, 일부 비상발전기에 적용한 실적 및 정부 지원 R&D를 토대로 지속적인 연구를 수행중에 있습니다

고정 오염원 촉매

발전소(화력, 바이오가스) 및 소각로, 제철소 등에 적용 가능한 중∙저온용 SCR 촉매를 개발하였습니다. 특히 바나듐계 및 제올라이트 계열의 촉매를 개발하여, 현장에 적합한 촉매를 제안할 수 있습니다.

VOCs 제거 촉매

화학약품 생산지, 메탈 프린팅, 인쇄소, 도장 공장 등에서 발생하는 BTEX(Benzene, Toluene, Ethylene, Xylene) 등의 가스를 직접연소 온도보다 낮은 온도(200~400℃)에서 무해한 CO2와 H2O로 제거할 수 있는 촉매를 개발하고 보유하고 있습니다. 최근에는 보다 저온에서 높은 효율을 나타낼 수 있는 촉매에 대한 연구를 수행중에 있습니다.

개인정보 취급방침

본사 : 충남 아산시 온천대로 1122번길 46-5 (득산동 312-26) Tel : 041-531-0657 / Fax : 041-531-0659

서울사무소 : 서울시 송파구 송파대로 260(가락동)제일오피스텔 906~907 Tel : 02-744-1777, Fax : 02-443-0054